| |

Estimate

Takeoff

|

|

Standard

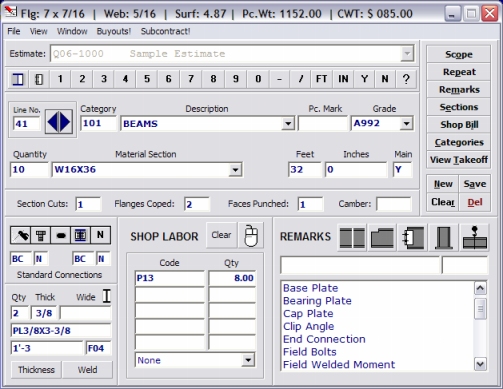

Takeoff Window

The system will

configure the takeoff window based on the type of material (W, PL, C,

etc.) that is being entered and is designed to accept input from top-left

to bottom-right. This means you do not have to jump around from window to window to enter

your estimate. While your estimators can enter data directly from your

drawings using a mouse or the

keyboard, estimates can also be taken off onto the supplied takeoff

sheets. This allows estimates to be prepared by estimators and entered

into the computer by clerical personnel.

In this example

the screen is configured to enter a beam, complete with all cuts,

copes, framed end connections and stiffeners. All material weights,

surface area, fasteners, paint, and fabrication labor will be calculated.

|

Fabrication being entered for this example:

(10)

- W16X36 beams as main members into fabrication category

101 - BEAMS, which automatically assigns ASTM A992 and a red oxide finish.

Saw

cut to length on one end only.

Two

flanges being coped.

Punched

on one face.

Shop

bolted, field bolted AISC standard framed connections on both ends. (During

takeoff, the

angles, bolts and / or weld used for these connections may be viewed and edited by clicking

either the Shop Bill button or the Material Connection

button.)

(2)

PL3/8 x 3-3/8 x 1'-3 stiffeners with 1/4 fillet weld. (The stiffener width

and length are sized automatically when you enter the thickness. You may

override by entering a different width.)

Punch

(8) 13/16" holes. (These are in addition to the holes that are

automatically punched for the end connections.)

|

| |

|

|

|

|

|

|

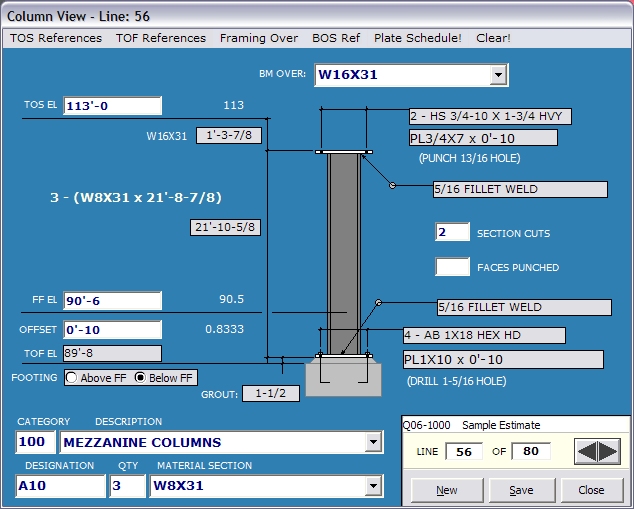

Optional Column Takeoff Window

Columns can be

entered in the standard takeoff window or using the Column View window.

The Column View window was designed to speed up the column takeoff process

by calculating column lengths from the data associated with columns. Using

it the estimator can takeoff the

top of steel and the top of footing

elevations or reference elevations along with framing

conditions. Base and cap plates as well as fasteners can also be applied

automatically from the Base and Cap Plate schedule. The system will calculate the column

length and apply all material, fasteners, paint, and shop labor.

Benefits:

| Material can be entered by typing or selection from

the drop-down box |

| Automated repeat keys can be used for material, labor

and connections, eliminating much of the typing |

| Predefined shop standards will automatically cut

material (saw, burn, shear) based on your shop preferences |

| Current mill or warehouse pricing is automatically

applied |

| Takeoff is standardized for all estimators |

| Labor is based on proven, time tested values |

|

|

|

Division 5 Software

Division 5 Software